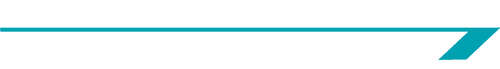

3D printing gives greater flexibility and more opportunities when designing and manufacturing complex parts. At Brown & Holmes, we use the latest 3D printer technology from Stratasys for our additive manufacturing which produces parts and prototypes from a wide range of materials including carbon fibre, polymers, acrylics, thermoplastics and polyurethane.

As durable as a traditionally manufactured part, this gives our customers the ability to use lighter materials and produce more complex, thermally stable and/or heat-resistant parts. What types of parts and fixtures can be 3D printed? If our in-house designers can model it, we can 3D print it directly from our CAD data and modelling programmes!

3D printing also gives additional functionality to our work-holding solutions. It allows us to make hybrid fixtures and assemblies. This in turn allows Brown & Holmes to provide our customers with an enhanced level of customisation and respond rapidly to market changes and make faster product improvements.

Design service for 3D parts

The Brown & Holmes designers love a challenge, and our 3D printers allow them to design and manufacture much more complex parts than conventional machining and traditional manufacturing allow. It also means that we can reduce the number of parts within an assembly reducing the bill of material complexity. We start by designing parts using our CAD programmes and then convert them into GrabCAD so they can be printed directly from our design office.

Our 3D Printers

Brown & Holmes currently use a Fortus 450 mc and an F170 3D printer for the additive manufacturing of parts, with two of our 3D printing machines producing parts in 17 different materials. Whilst we offer a design service, we can print parts from customers’ own designs and from a variety of CAD formats.

3D Printing Capacity

The capacity of our biggest machine is a 16” cubed envelope, however, we can print different parts and assemble or glue them together to make parts much bigger! Our machines run 24/7 so depending on the process, we can turn jobs around quickly, reducing lead times and meeting customer deadlines.

3D Print Services

Some of our customers need one-off, individual parts printing, for others we provide a sub-contract service to 3D print small batches of complex parts and assemblies.

Hybrid fixture manufacturing

3D printed parts can be used as part of a larger assembly that fits onto a traditionally manufactured fixture base and can incorporate hardened bushes. Many of our orders now use both conventionally manufactured parts and printed ones that are then assembled together.

3D printing offers customers a wide range of flexibility and we welcome enquiries from companies looking for innovative solutions. 3D printing is the perfect complementary service to traditional machining and cutting services and we can advise you on which method we feel is most suited.